Lanyards are accessories, which are essentially made from different yarns as raw material into narrow fabric or tubular fabric. Nowadays, the category of lanyard products is complicated and owns many different functions. It is widely used in the apparel industry, shoe industry, luggage industry and other industries. In the 1930s, lanyards are produced by artisans’ workshops. The most primitive materials for making lanyards are cotton thread, hemp thread and other textile lines. After the establishment of the People’s Republic of China, the raw material for making lanyards have increased, such as polyester, nylon, vinylon, spandex and so on. In the production process of lanyards, it has formed three kinds of technology, which included weaving, braiding and knitting. And the fabric structure is not uniform; it can be divided into several types, like plain weave, twill weave, satin weave, jacquard weave, double-layer weave, tubular weave and so on.

1.Weaving

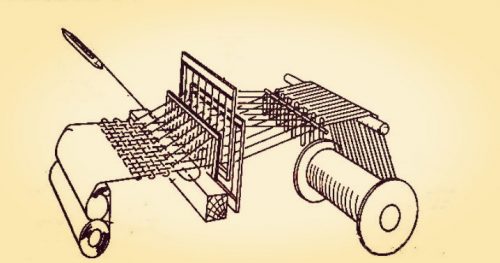

The basic process of weaving included the intertexture of warp and weft yarns. Intertexture of warp and weft yarns refers to that the twisted yarn is made into yarn bobbin, and then twisted the weft yarn on pirn in order to weave on the loom. In the 1930s, people use the hand-pulled wooden loom and iron loom. In the early period of the 1960s, the 1511 loom was converted into a weaving machine, which is still widely used in some small town workshops. In the 1970s, due to the promotion of the continuous dyeing and ironing machine, the processing for colored lanyards developed from dyed before weaving to weave before dyeing. The technology of the lanyards has entered into the ranks of mechanized mass production. In the 1980s, the lanyards technology has entered a new stage of development by introducing new machinery and equipment from abroad, such as high-speed shuttleless loom and warping machine.

2.Braiding

Meridian yarn tube and the volume has formed a weft tube and then inserted in the fixed gear knitting machine. The weft tube rotates along with an 8-shaped track to intersect knitting yarn traction. Generally, if the number of spindles is even, the lanyards are shaped like tubular; if the number of spindles is odd, the lanyards are flat sheet. The spindle number will change because of different equipment, but the range of spindle number is from 9 to 100. The basic technological process of braiding included: Bleaching and dyeing-Weft winding-Weaving-Cutting-Packaging. Since 1960, the braiding machine has undergone many technological innovations. The improvement of the device has increased the quality of lanyards and production efficiency.

Braiding machines not only can weave lanyards but also can weave rope. Tubular lanyards are a kind of customize lanyards, which is shaped like a shoelace. If your company or organization wants to advertise your goods or service for the public, choosing the custom made lanyards is the right thing.

3.Knitting

In the 1970s, weft knitting and warp knitting technology are widely used in lanyards fields. In 1973, the trial production of the tight-knit nylon wide belt is successful. By 1982 the Italian crochet machine was introduced and widely used in lanyards fields. As a new advanced crochet machine, it has features like advanced technology and a wide variety of products. The decorative fabric with thin features often uses the machine, which involved in lace, elastic tape, window screen and cummerbund. Actually, based on knitting principles, many other industries have created more products, such as fire hose.

Lanyards appeared in our daily life. The people work for supermarkets, company or competition need to wear the best lanyards to identify their position. Besides this, the lanyards also can advertise the brand, goods and services of your company. The promotional function can be applied to environmental protection and charity fields. Using high-quality lanyards or cheap lanyards on something significant is our duty for the whole society. If you want to know more information to customize lanyards, please visit GS-JJ.com. We have written detailed information on my Page.

Our website URL: https://www.gs-jj.com/lanyards/Custom-Lanyards

Email: info@gs-jj.com

Tel: 1-888-864-4755