PVC material can be made into many crafts, such as a keychain, luggage tag, labels, and patches. The products and crafts produced by PVC rubber are small and exquisite, which are loved by the masses.

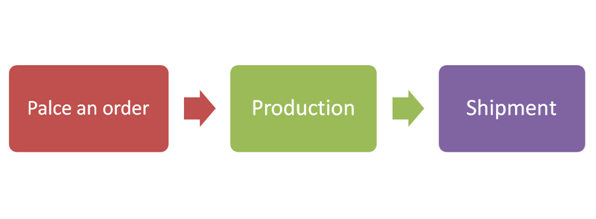

Taking a PVC patch as an example, the product from the order to shipment is divided into three parts. Here we give a detailed introduction about how to customize the PVC patch online?

When customers place orders at our GS-JJ Company, first they need to enter the product homepage and then to the customization system of the PVC patches page. Then the customer can order according to the process in the customized system. The process from placing an order to receiving an order by the factory can be roughly divided into the following steps.

1) When customers place an order, they need to select the product type, color, size, quantity, and other specific information in the customization system. Customers can also send emails directly to our customer service. We will provide the best-customized suggestions for customers.

2) After receiving the order, customer service will send an email to the customer to confirm the relevant information on the order.

3) Customers provide a design sample, and the company’s design team designs products based on the samples provided by customers.

4) Customers’ service sends emails to the client to confirm the design draft and order information.

5) After confirming the information, the merchandiser will place the order to the factory, and the factory will accept the order and then arrange the production.

Production process and craft

The factory will arrange production after confirming the order design. This part will introduce the production process and production crafts in detail:

- Open Mold: Factory open mold according to the shape and size of the PVC patch. The newer made mold includes the molded panel and the mold bottom plate which may close mutually. Production designers make a design sketch according to the requirements and use computers to engrave the mold.

- Mixing Materials: Mix all kinds of raw powdery materials in a certain proportion, and then use a blender to stir until it is smooth and transparent.

- Color Modulation: The prepared ingredients are divided into liquid material for surface text, liquid finish for pattern, bottom liquid of product, and add a variety of colorant liquid materials for color mixing and make into the color liquid for PVC patches. An epoxy color needs to be added onto the surface of PVC products. Usually, each color needs to drop color glue. If there are many color blocks, it needs epoxy color several times.

- Dispensing: Use the dispensing equipment to point the liquid material to the position of the molded panel that forms the text or pattern on the surface of the PVC patch.

- Baking: Point the mold with PVC liquid material for baking, drying, and then finalize the design.

- Heating: Heating the bottom liquid.

- Injection Material: Close the mold bottom plate on the mold top plate, and inject the heated bottom liquid material into the mold through the mold bottom plate.

- Baking Again: Bake the whole mold after injection, make the top liquid material, and the bottom liquid material bake together and then cool down.

- Demould: After baking, let the mold cool down, then take out the product and tear off the extra edges, and the production of PVC patch will be completed

Shipment Process

After the production of PVC products, it still needs to go through the following steps before the delivery to the customer’s hands.

Assembly –Part of the PVC patch will have Velcro and other accessories. If so, stitch the Velcro to the PVC part, then form the finished product.

Quality Inspection –When the product is finished, they will be sent to the quality control department, a quality inspector will inspect the product. Each product should do without bubble, trachoma, mix color, and the whole area clean, wool edge clip is meticulous just can accord with a standard.

Packaging –General PVC patches use a separate independent OPP bag packaging. The packing is well protected against dust and moisture. We can also customize the packaging according to customers’ needs. Then according to the order requirements, the product quota packing, it’s convenient for customers to check the quantity and inspection of goods.

Shipment – Due to the small volume of PVC patches, they belong to small-batch goods and are transported by air. Therefore, the delivery time is very short. Customers can receive the goods within 7 days. Of course, large goods are usually transported by land and sea; customers can choose their own mode of transport.

The PVC products produced by quality manufacturers are accord with export standard, environmental protection, and are nontoxic. They have bright colors, strong three-dimensional sense, clear natural pattern, and soft texture, light resistance, sweat resistance, cold resistance, friction resistance, and anti-aging, fadeless, water-proof, and other characteristics.

GS-JJ Company is one of the excellent manufacturers of custom PVC patches. We are constantly improving the production process and using professional environmental protection materials. No matter for other craft products or PVC soft rubber products, we are always producing high-quality products with high-quality raw materials.