Although many wristbands are still manufactured with other synthetic rubber materials, the majority of today’s wristbands are made from silicone material.

Silicone’s popularity comes from its advantages such as environmental protection, non-toxic, insipidness, flexibility, and so on. It is also water-resistant and won’t shrink easily. In addition, one of its biggest features is that they are easy to customize. Customers can customize personalized messages, colors, and sizes to fulfill personal needs when ordering wristbands. The multitudinous design and reasonable cost performance give a boom in sales of custom-made wristbands.

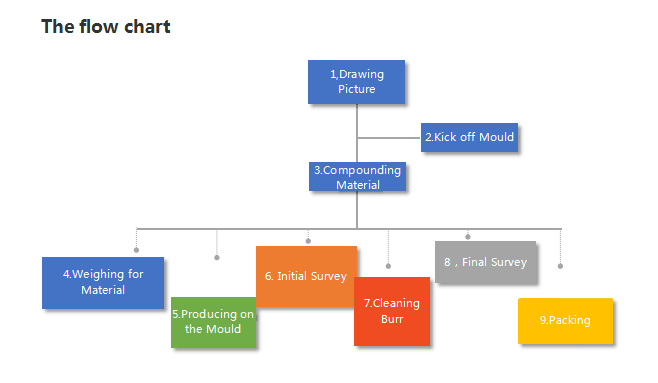

Since we know the popularity of customized wristbands, do you want to go further and know how to make wristbands? Here we offer a thorough explanation of the making process of wristbands. There are altogether nine steps.

Details for the Production Process

- Drawing the Picture First

Drawing the design is generally based on the requirement of customers, which can be provided by the customer and can cooperate with the customer to complete the design and production of drawing as well.

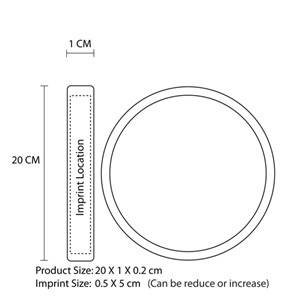

The drawing should contain the demands of color, size, post-process, etc.

Choosing the right color is critical for making wristbands as the color probably is the soul of the bracelets. You have to decide which colors you want to use for background colors or the logo and text. It is a reflection of the theme of your wristbands.

In terms of sizes, here are a few references: if the attendants of the event or party are all adults, you can order customize size wristbands for adults. If there are kids involved, looking for wristbands for kids as well.

Picture source from https://www.keepitpromo.com/index.php/el/component/virtuemart/promotional-health-and-safety-items-with-logo-print/recognition-silicone-wristband-detail?Itemid=0

- Kick-off Mold

Once the drawing is approved, it is time to prepare the mold.

The mold is produced with steel according to the drawing.

Some bracelets have complicated crafts, such as embossed and debossed crafts, so the productive processes of mold may be relatively difficult because we will have grooves and patterns embedded onto the mold to show out the embossed or debossed text and icons. So more time will be spent to complete and the lead time of mold will be around 5-7 days.

Compared with the embossed and debossed crafts which directly process on the mold, the printed craft is relatively simpler than the two. So you can choose not to have your wristbands embossed or debossed but rather printed with a design using high-quality inks or paints. Once the silicone material is formed into the “wristband” shape in the mold, it will be printed with the appointed contents. So, the mold for printed wristbands will be quicker than the two crafts we mentioned above.

Picture source from http://www.kawashima-kinzoku.co.jp/ch/

- Compounding Material

After the mold is ready for production, the material should be prepared. According to the specified color, we should put the toner into raw material and mix up so that they are well-proportioned. In order to avoid getting the wrong color, please confirm the color with the Pantone Color Chart.

In addition, other essential ingredients should be put into the mix at the same time.

- Step 4: Weighing for Material

After processing, the prepared material will be covered with a thin sheet of plastic and then passed through a machine to be cut into strips. The material strips are then weighed by an electronic scale to ensure that the weight of each strip is within the positive and negative tolerance, which is the key to ensure each wristband has the same appearance and similar weight after molding.

Besides, bracelets of different styles and sizes also vary in the amount of material used.

So, it is one of the essential steps in making wristbands.

- Step 5: Production

Now, mold is installed, materials stand-by, so we will place the material strips into the mold cavity, and then we will start the production of custom-made wristbands.

But the most important is that we need to adjust the parameters of the machine first, and then wait for the temperature of the machine heated up to an appointed degree, generally around 200 degrees. This is to ensure all bracelets can complete the forming process well. That’s also the reason why silicone bracelets are so resistant to high temperatures.

Picture source from http://cotocm.com/capabilities.html

- Step 6: Initial Survey

After production, we should have an initial survey for all products. Checking if there are some wristbands broke, damaged, and so on. All unqualified products will be disposed of.

Picture source from https://signaturepins.com/custom-wristbands

- Step 7: Cleaning Burr

After the initial survey, we should send these semi-finished wristbands to Process Department for further trimming.

Picture source from:

- Step 8: Final Survey

Before packing, we should return the finished bracelets to the QC department for final checking. Mainly checking whether they are in compliance with the inspection standard.

- Step9: Packing

After the final checking, we will pack the custom-made wristbands, seal the box, and send it to the warehouse for delivery.

Picture source from https://mackemployment.com/about/

Usually, custom-made wristbands are associated with various activities, fundraising, and charitable events, brand promotion, sports, etc. Silicone wristbands can be used as personalized gifts, such as the 12 Constellations Wristbands; used to drive away annoying mosquitoes; used as fashion accessories in any season.

Whatever application of wristbands you decide to go with, just keep in mind a good and unique design can convey a profound meaning and go a long way. Besides, wristbands almost suit for everyone to wear for their low cost and eco-friendly features.

Through the introduction above, have you ever found that small custom-made wristbands contain rich technology and many production processes? GS-JJ is a passionate company, which is trustworthy, professional, and customer-oriented. If you are interested in the production process or other details about bracelets, welcome to go to the website www.gs-jj.com directly, which is a wonderful place to create custom wristbands with cheap prices and no minimum order.